How to choose between a deck oven and a modular oven?

Sole ovens and modular ovens are two types of professional ovens designed for artisan bakers. While they are similar in many technical aspects, particularly in terms of their heating function, they differ in their accessories and compactness and can offer very different uses.

What they have in common:

⚡️ Energy:

First and foremost, modular professional ovens should be compared to professional electric deck ovens, which are the most widely used and offer the most flexible and therefore the most economical use for small and medium-sized production runs, despite the initial energy cost (price per kWh).

🥐 Baking quality:

Both types of oven are renowned for their even and precise baking. They use electric heating elements and refractory slabs that provide ideal radiant heat for baking traditional bread and baguettes. This guarantees a crispy crust and a soft crumb, characteristics that are highly prized in artisan baking. They have very similar characteristics in terms of heating power, insulation thickness, and baking capacity.

🐙 Versatility:

Thanks to their stand-alone design, these ovens can be easily adapted to any production setup. They are ideal for periods of high demand, such as in the morning before restaurant deliveries or for small replenishment orders during the day. However, it is important to note that these models require a lot of energy to reach the required temperature and thus guarantee the baking inertia for which they are renowned. They can accommodate different tray and rack formats but are also very suitable for direct baking on the sole, allowing a wide variety of breads and pastries to be baked. Their independent modular design allows different preparations to be baked simultaneously, thus optimizing production.

🌱 Durability and Added Value:

The design of the cooking chambers and the heating elements are identical in both professional deck ovens and modular ovens, based on robust, proven materials with dimensions calculated for durability: stainless steel, aluminized sheet metal, reinforced heating elements, diffusion plates, refractory stone sole, etc. They are designed to be installed in demanding working environments and to deliver consistent results every time.

What sets them apart:

The deck oven is a solid, immobile oven that is installed in the bakery for the long term. It is the central piece of the bakery, and the workspace is arranged around it. It is also connected to the chimney system via large-diameter, rigid pipes designed for high flow rates. Similarly, the deck oven is connected to the water supply and steam extraction system, which is designed for high production, helping to keep the oven stationary.

It is also often equipped with an altar table used to place trays and loaves when they come out of the oven, which contributes to its solid appearance.

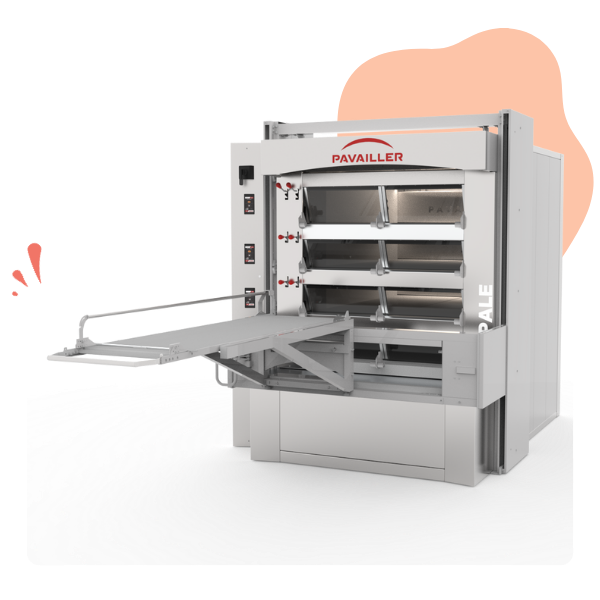

The modular oven, on the other hand, is more compact and is mounted on a wheeled base, often openwork, which gives it a lighter appearance despite its large size to support its weight. It is designed to accommodate trays, although it can be equipped with an integrated oven loader, allowing baking directly on the hearth. Its electrical and hydraulic connections are often made of flexible materials to take advantage of its mobility, which is made possible by the wheeled base.

The benefits of a deck oven

1. Cooking surface:

Professional deck ovens are generally available in models ranging from the smallest surfaces (3 to 4 m² of cooking space, such as modular models) to large surfaces, spread over 4 or even 5 levels and 2 or 3 lanes, allowing them to exceed 20 m² of cooking space. It should be noted that for ovens of this size, it is necessary to consider the energy source to be used. In the case of very large deck ovens, a combustion model (gas, fuel oil, or wood) should be considered.

2. Loader:

The vast majority of deck ovens are installed with integrated loading elevators, which are large accessories. They are designed to be handled very frequently and are the part of the oven that is most subject to stress and wear. They are therefore supported by imposing pillars.

3. Energy savings:

Modern deck ovens are designed to be energy efficient. They optimize energy consumption while increasing productivity, which is crucial in a context of high energy costs. This is generally achieved through the collective intelligence of electronic cards that communicate with each other. Thanks to this system, their power consumption can be capped, making them suitable for connection to EDF's blue tariff (36 kVA limit).

The benefits of a modular oven

1. Scalability and adaptability:

Professional modular ovens offer great scalability with their independent cooking chambers. This allows you to start a business with two cooking levels and invest in a third one that is very easy to install when your shop becomes successful and requires a larger production capacity.

2. Practicality:

These ovens are often equipped with bases or compartments for storing equipment such as trays and proofing baskets.

3. Versatility:

Modular ovens can be used for a wide range of products, from traditional breads to pastries. Their ability to adapt to different types of production makes them an ideal choice for bakeries looking to diversify their offering. There are specific models for baking, suitable for rack ovens and with a good steam generator, for pastry, suitable for tray baking with a specific door, or for pizza with a suitable baking temperature and height.

4. Compactness:

Designed to be compact, these ovens are perfect for bakeries with limited space. They offer an efficient solution without compromising on production quality or quantity.

Investing in a deck oven or a modular oven is a strategic decision for any artisan baker. Deck ovens are ideal for those who prioritize large production runs and traditional quality and authenticity, while modular ovens offer flexibility and energy efficiency tailored to modern needs. Each type of oven offers unique benefits that can contribute to the profitability and reputation of the bakery.