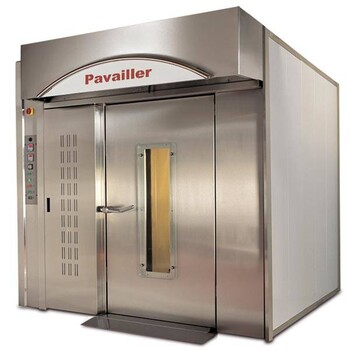

Rotary rack ovens

Pavailler rotary rack ovens are designed for all types of production: fresh, raw, frozen, and pre-cooked frozen. The baking of your breads or pastries will be regular and of high quality thanks to the homogeneity of the hot air circulation and the rotation of the rack. This baker's oven is available in 3 versions: oil oven, gas oven and electric rotary oven.

Our range of products